Fire Resistance Curves for Tunnels

In terms of fire resistance (1634-1), there are variations of the standard ISO 834 curve.

The HCM curve (Modified Hydrocarbon Curve) is mainly used in France since the tragedy of the Mont Blanc tunnel in 1999, in which 39 people lost their lives. This curve was designed to illustrate the extremely rapid temperature rise that occurs during fires in confined spaces. It is now used to certify the fire resistance of doors that will be used in tunnels.

The RWS curve, named after the Ministry of Public Works of the Netherlands, “Rijkswaterstaat”, which manages highways and thus the numerous tunnels in the country. This curve follows a similar trajectory.

The RABT curve, developed in Germany, follows the RABT guidelines (Richtlinien für die Ausstattung und den Betrieb von Straßentunneln) and ZTV regulations (ZTV-ING, etc.). It accounts for an intense fire, but of shorter duration than the RWS curve.

The temperature curves

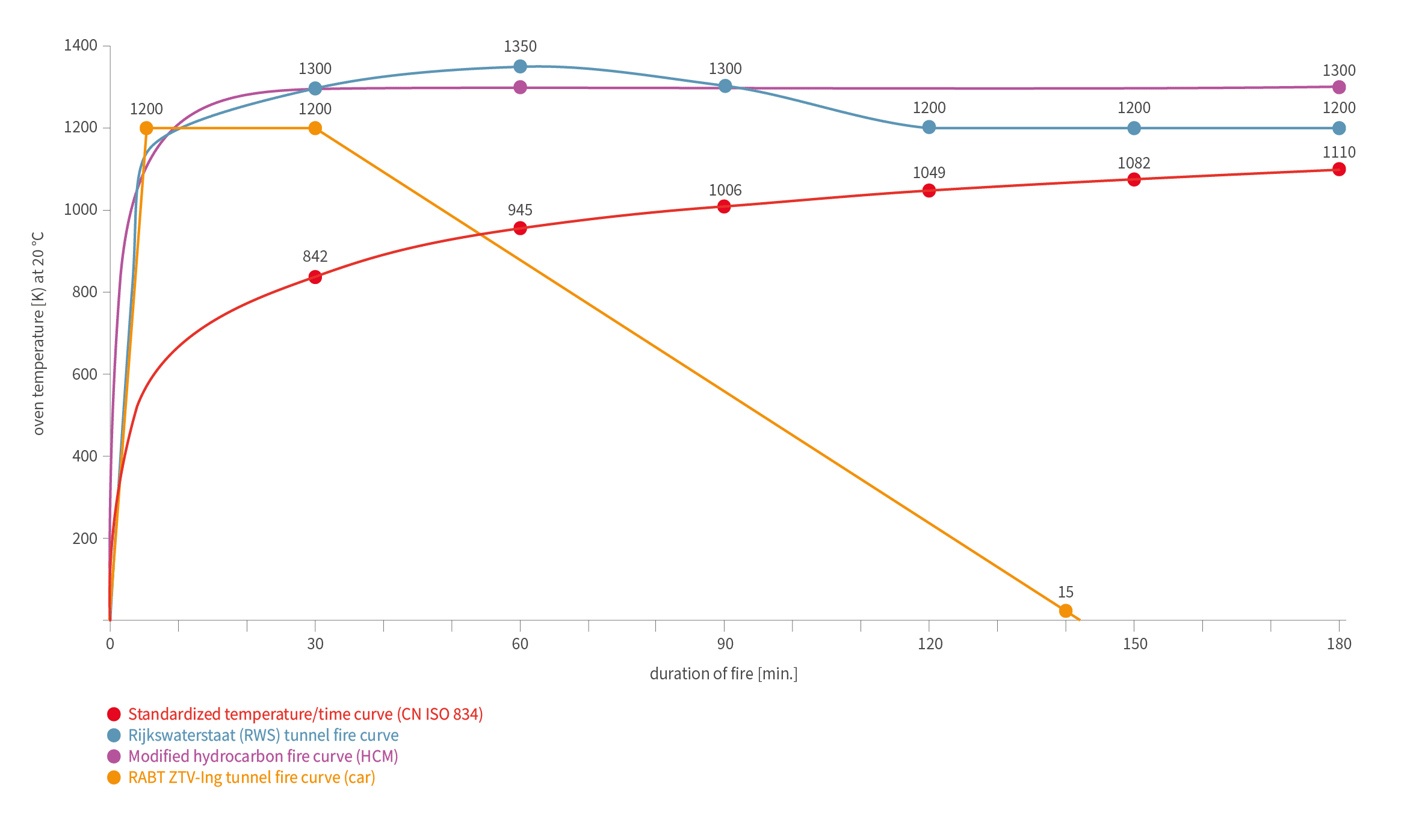

The ISO 834, RWS, HCM, and RABT-ZTV fire curves are standardized representations of the temperature evolution over time during a fire. They serve as references for sizing or verifying the fire resistance of specific structures (buildings, tunnels, industrial installations, etc.). Each of these curves corresponds to a given fire scenario and presents different rates of temperature rise and maximum temperatures.

The ISO 834 curve

The ISO 834 curve is the most well-known and widely used for the fire resistance of buildings. It has a gradual rise. After 2 hours, the temperature can exceed 1000°C without any defined cooling phase (it is a continuous rise).

The RWS curve

The RWS curve (Rijkswaterstaat) was developed in the Netherlands for extremely severe fire scenarios in tunnels, particularly for hydrocarbon fires (tank trucks, fuel transport). It reaches 1350°C within 60 minutes. It remains at a very high level for 2 hours (120 minutes) before dropping to 1200°C in the final phase.

The HCM curve

The Modified Hydrocarbon curve (HCM) is often used in France and internationally for tunnels and hydrocarbon fire scenarios (petrochemical platforms, etc.). It has a rapid temperature rise and reaches 1100°C within 5 minutes. It will reach its maximum temperature of 1300°C in 30 minutes.

The RABT ZTV curve

The German RABT fire curve is specific to road tunnels. It accounts for an intense fire but of shorter duration than the RWS curve. It reaches a plateau at 1200°C within 5 minutes and maintains it for 30 minutes, after which the temperature drops sharply. This curve assumes that the calorific load is consumed quickly.

Modified Hydrocarbon according to French regulations

Three levels of resistance have been defined for tunnel doors:

| Level | Fire resistance on the ISO 834 standard curve* | Fire resistance on the HCM curve* |

| N1 | 120 minutes | – |

| N2 | 120 minutes | 120 minutes |

| N3 | 240 minutes | 120 minutes |

* Successful criteria E (fire resistance) and I2 (insulation)

Heinen tunnel doors and HCM doors

Tunnel doors or HCM Heinen doors have met the requirements of the highest level, namely level N3: HCM120 / CN240.

These doors are available custom-made, in single and double versions, and can combine various performances (acoustic, anti-burglary, etc.) to adapt to different situations in tunnels. If necessary, they are also equipped with evacuation mechanisms (panic bars or bolts) to comply with European standards EN 1125 and EN 179.