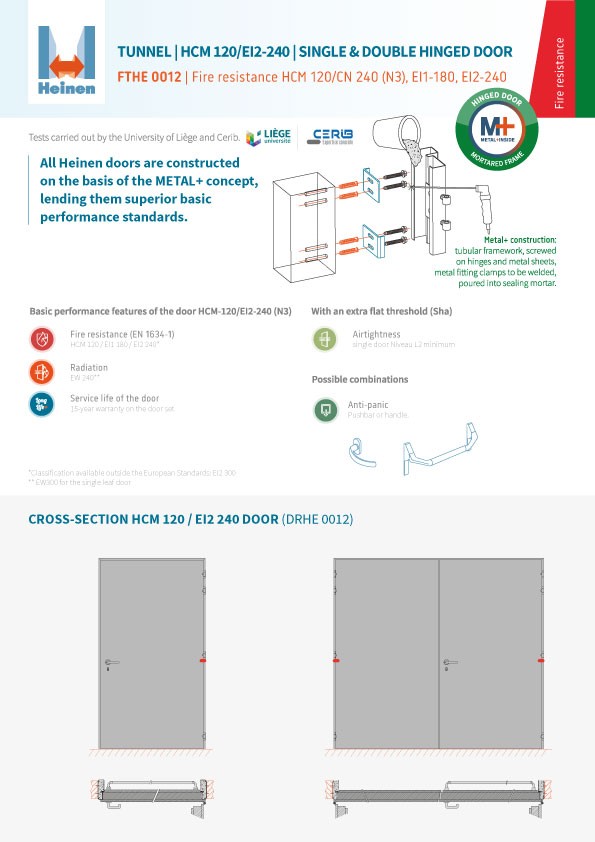

Heinen HCM fire resistant doors

Tested according to the modified hydrocarbon curve

Heinen develops fire doors for a wide range of applications. Many of our products are tested according to European standards using the standardized ISO 834 curve, which takes into account the temperature rise of a “standardized” fire to determine fire resistance (e.g., EI1 30, EI1 60, EI1 120…).

In contrast to the ISO curve, the HCM (Modified Hydrocarbon) curve has a rapid temperature rise and a high plateau at 1300°C. Heinen has developed single and double HCM N3 doors, fire-resistant on both the hinge side and the opposite side of the hinges.

Tunnel doors

Fire-resistant doors in tunnels must meet much stricter requirements than standard doors, which typically follow the ISO 834 curve. This standardized curve is used to test fire resistance under standard conditions, but it does not account for the specific characteristics of environments such as tunnels. In these environments, fires can develop much more quickly and violently due to the accumulation of heat and the lack of sufficient ventilation to expel the hot gases.

Since the 2000s, the requirements for fire-resistant doors in tunnels have been strengthened to address these challenges. Fires in these confined spaces are often more intense and can reach much higher temperatures than in a standard building. Additionally, the confined conditions in tunnels cause the fire to spread more quickly, making the role of fire-resistant doors crucial in limiting damage and enabling a safe evacuation.

A fire-resistant door in a tunnel must be able to withstand a much faster rise in temperature than under normal conditions. Fire resistance tests in such structures are therefore adapted to simulate the reality of fires in these extreme environments. The specific standard for tunnels takes into account not only thermal resistance but also the duration for which the door must remain functional to ensure the safety of users and allow for the intervention of emergency services.

HCM fire resistant door performance

The HCM fire resistant door (tunnel) offers exceptional fire resistance performance. Designed to withstand extreme conditions, it is certified HCM 120 and EI2-240, meaning it can withstand temperatures up to 1300°C. Thanks to the HCM (Modified Hydrocarbon) curve, the door is subjected to a rapid temperature rise, simulating high-intensity fires, such as those often encountered in tunnels. This performance allows it to maintain its integrity and provide a reliable barrier against flames and heat.

For 120 minutes (HCM 120), the door maintains its fire resistance properties, providing effective protection against the spread of fire. It continues to maintain airtightness and stability for up to 240 minutes (EI2-240), ensuring prolonged protection under severe fire conditions. This helps contain the flames, protect occupants, and offer maximum safety during the initial stages of a fire.

The design of this door allows it to withstand high temperatures while preserving its structure, which is crucial in environments such as tunnels or high-risk areas. Its ability to endure these extreme conditions makes it an optimal choice for sensitive infrastructures where fire safety is essential.

Doors with cumulative performance

In addition to their long protection life and particularly wide range of sizes, Heinen doors can be combined with other performance features “à la carte”. Depending on your needs, one or more performances can be added to the basic METAL+ door.

Basic performance of the HCM fire resistant doors

Possible combinations

Anti-panic

Fire resistance door

Smoke tightness

View

our data sheets and BIM objects

Download the Heinen door specifications

You want to configure your doors combining bespoke performance features. You want to download BIM objects in various formats. Go to our Specifications and BIM section.